How to select a profile diffuser?PC or PMMA?

How to select a profile diffuser?PC or PMMA?

Acrylic often compared to Polycarbonate, which is an other transparent plastic, that is sometimes used for bearing loads. Polycarbonate is sometimes called Lexan®, which is a trademark by GE Plastics. An other popular brand name for Polycarbonate is Makrolon®, owned by Bayer. Acrylic on the other hand is often called Plexiglas. Plexiglas ® is a trademark by Roehm and Hass.

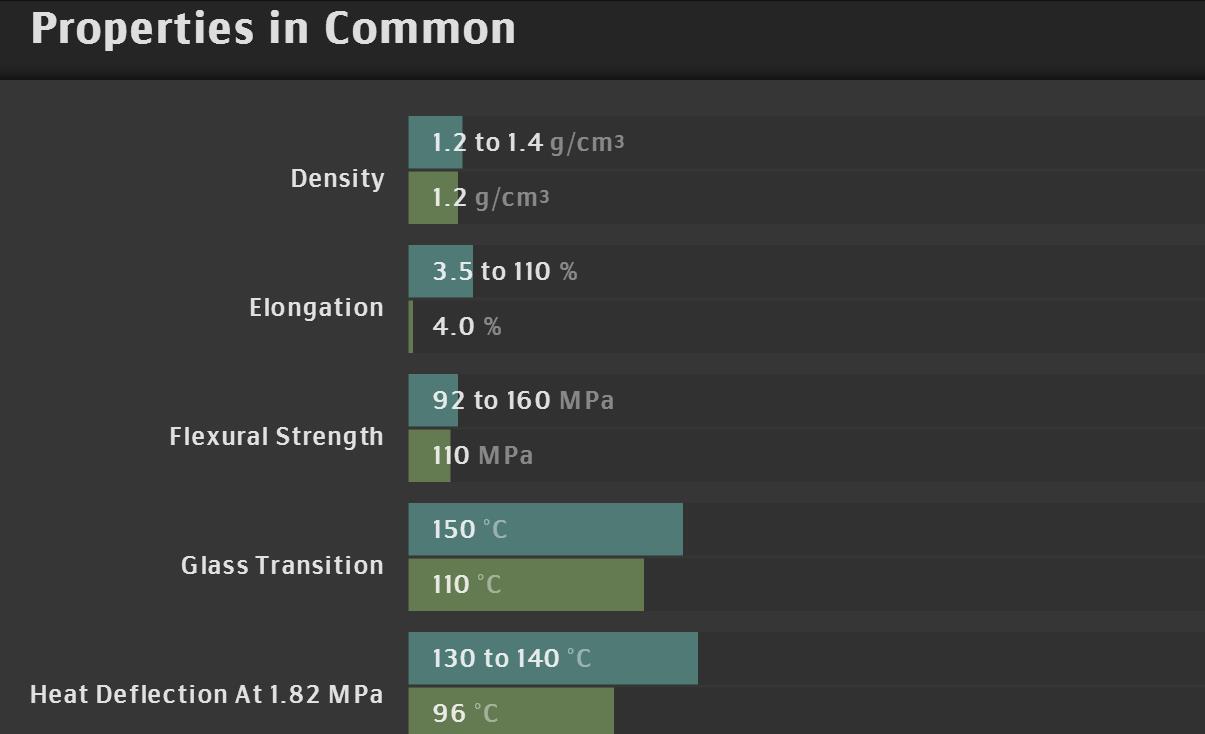

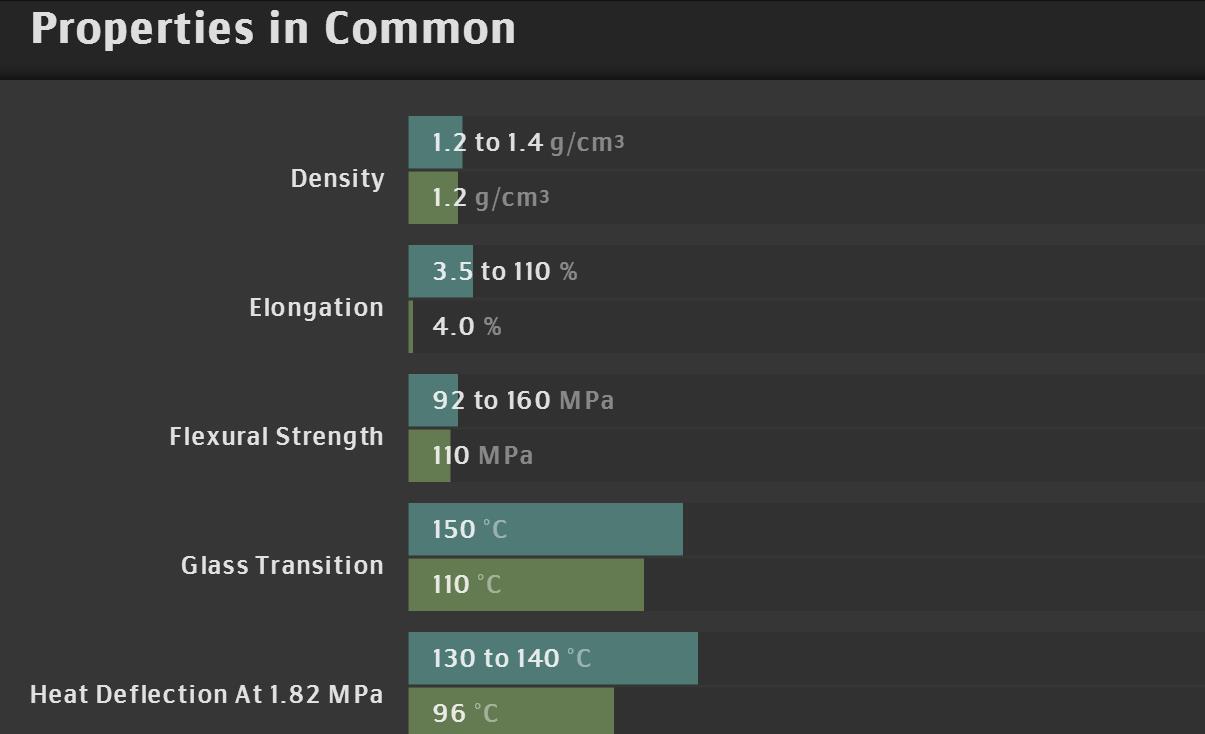

Key characteristics, Acrylic compared to Polycarbonate:

- More likely to chip less impact resistance then Polycarbonate, but still 10-24 times more resistant than float glass

- more resistant against evenly distributed loads then Polycarbonate Less likely to scratch.

- Does NOT yellow after time. Better clarity. Acrylic can be restored to optical clarity by polishing.

Key characteristics, Polycarbonate compared to Acrylic:

- Impact/chip resistance is much higher with Polycarbonate. (about 30 times more resistant than glass)

- More likely to scratch. Substantially more expensive. (roughly 2 to 3 times)

- Used for more industry applications Bulletproof when thick enough.

- More bendable under normal temperatures (0-20°C) Yellows over time due to ultraviolet rays Easier to work with (cut, less likely to break) Poorer clarity, diffuses light

Thetalight offer both PMMA & PC diffuser which could fullfill most of clients requirement!

Contact Thetalight now for more choice. sales@thetalight.com